Screen printing: process advantages, details and clothing adaptation guide

Significant advantages of screen printing

Excellent color expression:

It can use a variety of inks such as water-based and solvent-based inks to present bright and rich colors, especially good at printing high-saturation patterns. Through multiple color printing, it can achieve rich color levels and gradient effects to meet the needs of complex patterns.

It can use a variety of inks such as water-based and solvent-based inks to present bright and rich colors, especially good at printing high-saturation patterns. Through multiple color printing, it can achieve rich color levels and gradient effects to meet the needs of complex patterns.

Strong three-dimensional sense and texture:

Compared with other printing processes, the ink layer of screen printing is thicker, generally up to 10-30 microns, giving the pattern a distinct three-dimensional sense and texture, and a stronger visual impact.

Compared with other printing processes, the ink layer of screen printing is thicker, generally up to 10-30 microns, giving the pattern a distinct three-dimensional sense and texture, and a stronger visual impact.

Wide range of material adaptability:

It can be printed on almost any flat or curved substrate, from soft cotton and silk to hard plastic and metal, and is particularly suitable for use in the clothing field.

It can be printed on almost any flat or curved substrate, from soft cotton and silk to hard plastic and metal, and is particularly suitable for use in the clothing field.

Small batch customization is cost-effective:

For small batch printing or personalized customized clothing, the cost of screen printing is relatively low. The cost of making the screen is relatively fixed, and the screen can be reused, reducing the cost of a single product.

For small batch printing or personalized customized clothing, the cost of screen printing is relatively low. The cost of making the screen is relatively fixed, and the screen can be reused, reducing the cost of a single product.

Fine process details

The core of screen printing is the screen plate, which is composed of a screen, a screen frame and photosensitive glue. When making it, the designed pattern is first made into a film; then the photosensitive glue is evenly coated on the screen plate, and after drying, the film is placed close to it for exposure. After exposure, the photosensitive glue on the transparent part of the film is solidified, and the photosensitive glue on the black part is washed away during development, thus forming a hollow pattern on the screen.

When printing, fix the screen plate on the printing machine, place the substrate (such as clothing fabric) below, pour the ink, and use a scraper to scrape at an angle of 45° - 60° and appropriate pressure. The ink is transferred to the clothing through the hollow part of the screen, and multiple color overprinting can complete the colorful pattern printing. After printing, dry it according to the type of ink to ensure that the pattern is firm.

Suitable clothing types

T-shirts: Whether it is a street fashion brand's personalized slogan T-shirt or a simple style basic printed T-shirt, screen printing can present the pattern clearly and vividly, and is a common process for T-shirt printing.

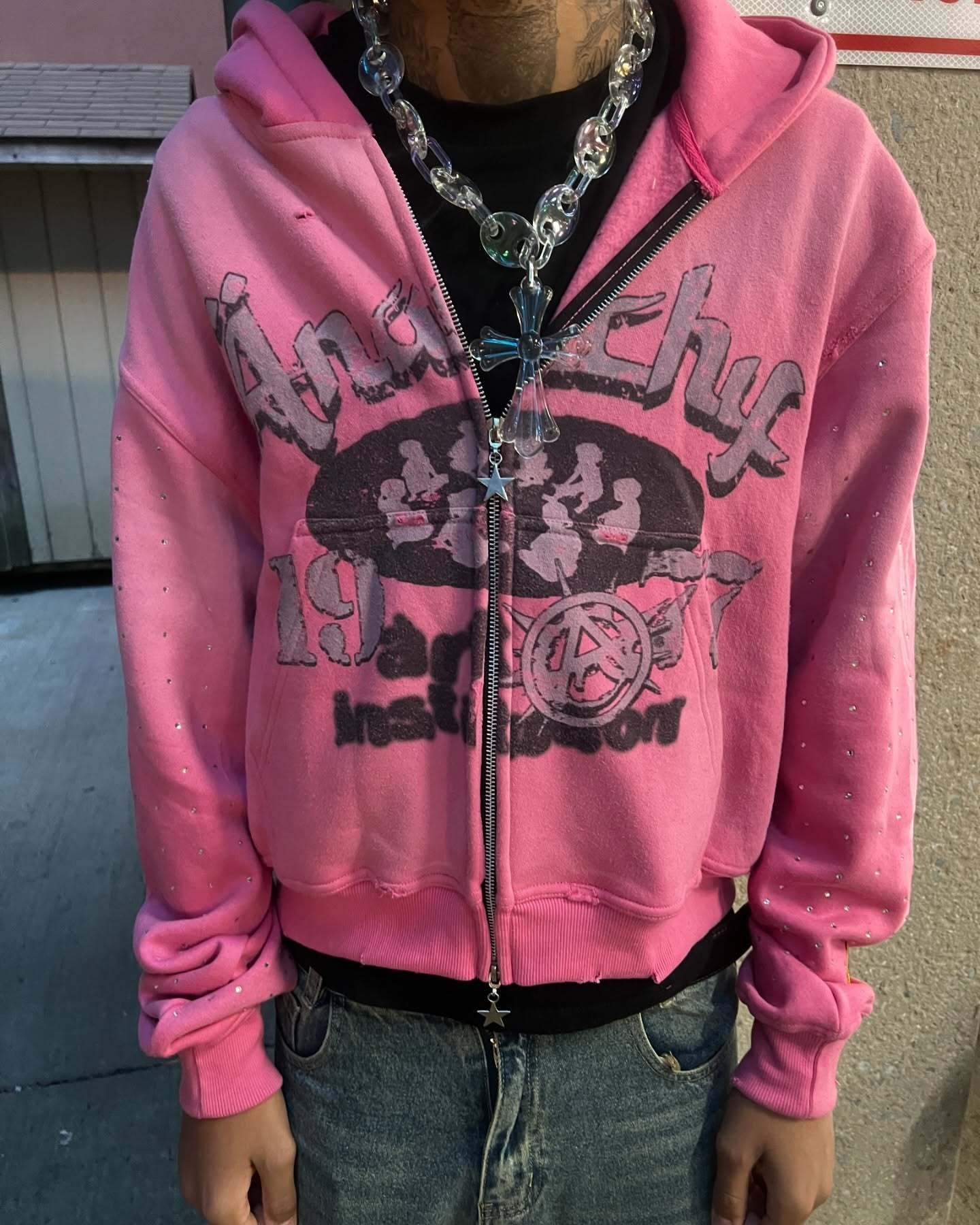

Sweatshirts: On sweatshirts, screen printing can create patterns in a variety of styles such as retro, trendy, and artistic. The thick ink layer makes the pattern more textured and enhances the overall fashion sense of the sweatshirt.

Denim clothing: Denim jackets, jeans and other denim clothing can be added with unique patterns and colors through screen printing, which complements the texture of denim and shows personalized style.

Fashion dresses: Art print dresses from high-end brands often use screen printing technology to print exquisite patterns and designs on the fabric, highlighting the elegance and design sense of the clothing.

Accessories: For accessories like canvas bags, hats, etc., screen printing can give them rich patterns and colors, making them the finishing touch in the outfit.

Sweatshirts: On sweatshirts, screen printing can create patterns in a variety of styles such as retro, trendy, and artistic. The thick ink layer makes the pattern more textured and enhances the overall fashion sense of the sweatshirt.

Denim clothing: Denim jackets, jeans and other denim clothing can be added with unique patterns and colors through screen printing, which complements the texture of denim and shows personalized style.

Fashion dresses: Art print dresses from high-end brands often use screen printing technology to print exquisite patterns and designs on the fabric, highlighting the elegance and design sense of the clothing.

Accessories: For accessories like canvas bags, hats, etc., screen printing can give them rich patterns and colors, making them the finishing touch in the outfit.